An industrial floor is essential in many industrial facilities. They have to withstand heavy loads, such as heavy machinery and vehicles, chemicals, abrasion and moisture. The coatings are designed to be more robust and durable than conventional flooring. They also offer benefits such as easy cleaning, increased safety and versatile adaptability. Here we show you the benefits and different types of industrial flooring.

Contents

What is an industrial floor?

An industrial floor is a specially designed floor covering that is used in industrial environments. These floors are designed to withstand the demands and stresses of industrial and commercial operations. They must be resistant to mechanical loads, chemicals, temperature fluctuations and other specific conditions that can occur in industrial environments. Industrial floors are made of resistant materials that are specially adapted to the requirements of the respective operation.

The flooring in an industrial plant is of crucial importance to ensure occupational safety. A slippery or damaged floor can lead to serious injuries and impair production.

In addition, operating materials and other liquids pose a risk to groundwater if they penetrate damaged soils and contaminate the subsoil. The Water Resources Act sets out clear requirements regarding the quality of many industrial soils.

This is why coatings in industrial facilities are created to make operations efficient and safe, increase productivity and meet legal requirements for environmental protection.

Industrial flooring - advantages

An industrial floor offers numerous advantages for companies that rely on a robust and durable flooring solution. Here are some of the key benefits:

Robustness

Industrial floors are known for their high robustness and can withstand the daily stresses that occur in an industrial environment. They are resistant to heavy machinery, vehicles and loads that are often placed on them. This makes them ideal for warehouses and factories where heavy objects are transported or placed on the floor.

Longevity

Due to their robustness and the choice of materials, industrial floors are also characterized by their durability. The high resistance and durability of the flooring mean that companies save costs in the long term thanks to long maintenance intervals and low repair costs.

Easy cleaning

Industrial floors are easy to clean and maintain. Regular cleaning of the floor is important to ensure a safe and hygienic working environment. A variety of cleaning agents can be used that have been specially developed for the requirements of the floor covering in question.

Security

An industrial floor provides a safe working environment for employees by being non-slip and resistant to chemicals and other substances. The surface can be provided with a non-slip coating to minimize the risk of falls and injuries. A safe workplace is not only important for employees, but also for the productivity of the company.

Adaptability

Industrial floors can also be adapted to the specific requirements of a company. Different flooring systems are used depending on the purpose and requirements. The surface of the floor can be provided with special markings or colors to demarcate areas or to make the workplace clearer and safer. Forklift routes, escape routes and walkways can also be marked in this way.

All these advantages make industrial coatings an important investment for companies looking for a robust and durable flooring solution.

Industrial flooring - types

There are various types of industrial coating systems that are suitable for different purposes. Below we present our portfolio of industrial floors:

Mortar floor

A mortar floor is a flooring system specially manufactured for use in industrial environments. It consists of epoxy resin and particularly fine quartz sand. The finished floor is provided with a pore seal and sealed. A large selection of colored quartz allows for visual customization.

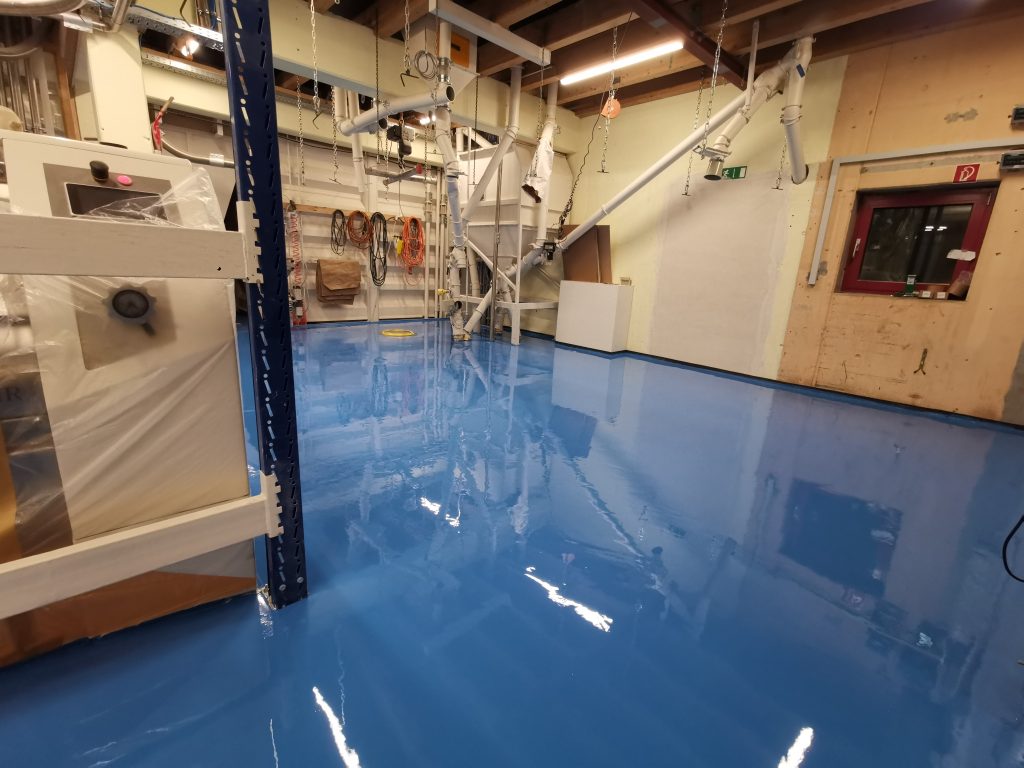

Cast floor

Industrial cast floors made of epoxy resin can be found in many areas of application today. Special epoxy resins and fillers produce a cast layer just a few millimeters thick that is highly resilient and very resistant to chemicals. These coatings can also be produced in any RAL color to improve aesthetics.

Industrial cast flooring, installed by Qubo® Altenkirchen

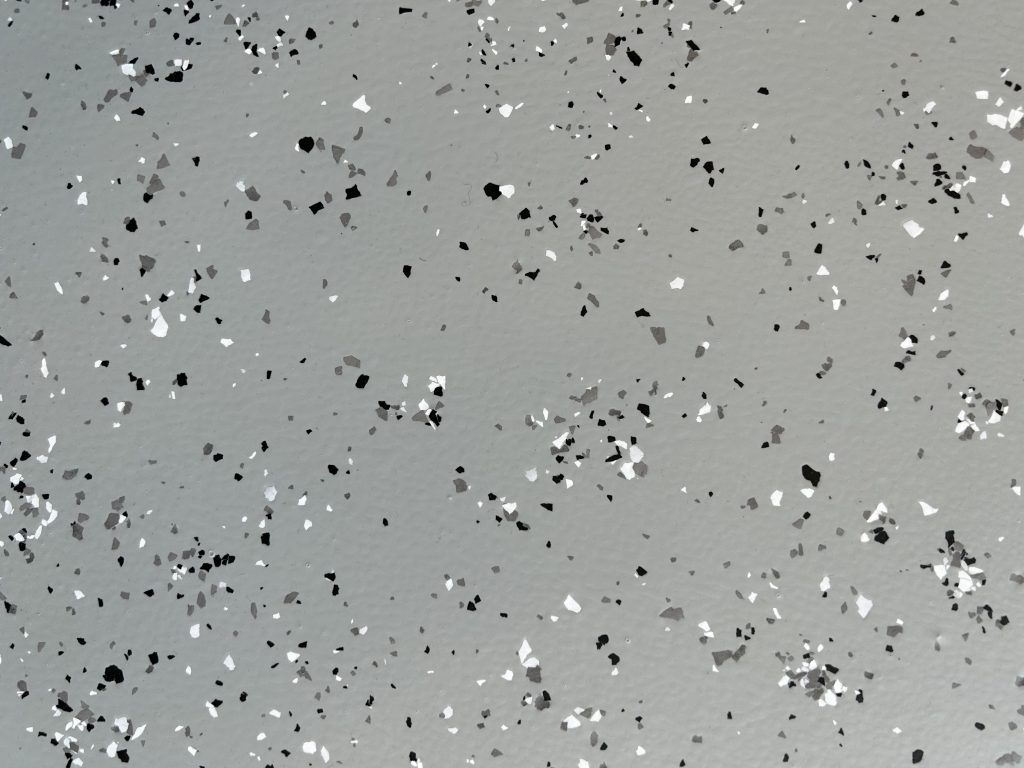

Bedding coating

Poured floors are referred to as infill coatings when special color chips are sprinkled into them during installation. These change the appearance of the coating and thus offer an additional option in terms of design freedom. The system is sealed after installation.

Scatter coating

Similar to the mortar floor, scatter coatings are created from epoxy resin and quartz gravel. With this system, however, the material is not mixed before laying. The special industrial resin is applied to the floor as a thin layer and sprinkled directly with gravel in excess. As it hardens, large parts of the gravel bond with the resin, forming an impact-resistant surface with a very low build-up height. The excess – i.e. the gravel that has not bonded with the resin – is removed after the curing process using high-performance vacuum cleaners. Finally, the system is sealed with epoxy resin.

The skid resistance of the scattered floor changes depending on the gravel grain size used for scattering. Special requirements and legal specifications are clarified in advance of the construction work and the floor is prepared accordingly.

Where industrial floors are used

Coatings with reactive resins in particular are used in various branches of industry. Typical areas of application for such floor coverings include dairies, commercial kitchens, cold stores and the meat processing industry. These places place high demands on hygiene and freedom from dust.

Industrial flooring is also used in the medical sector, where hygiene is particularly important in production facilities, surgeries and laboratories. Premises with high public traffic, such as exhibition halls, shopping centers, stores and fitness studios, are equipped with the robust flooring systems.

Due to their durability, they are also frequently used in public facilities such as government buildings or airports. Industrial floors are also installed in garages and workshops.

The main area of application for industrial flooring is in industrial manufacturing companies. There are many reasons for this:

-

Durability: In industry, there are often heavy machines, vehicles and material movements that put a lot of strain on the floor. An industrial floor is robust and resistant to mechanical stress and wear, making it able to withstand daily demands.

-

Chemical resistance: Chemicals, oils or other aggressive substances are often used in industrial environments. Our flooring systems are resistant to chemicals and prevent damage or discoloration caused by contact with these substances.

-

Slip resistance: Qubo® coating systems can be equipped with anti-slip properties to minimize the risk of accidents caused by slipping or tripping, especially when there is a risk of liquids or production waste on the floor.

-

Thermal resistance: Depending on the type of production, hot production machines and high room temperatures place increased strain on floors. An industrial floor can easily withstand large temperature differences.

-

ESD protection: In the electronics industry or other areas where electrostatic discharges can be harmful, an antistatic industrial floor can be used to protect electronic components.

-

Fire protection: In some industries where there is an increased risk of fire, the flame-retardant properties of Qubo® coatings contribute to fire safety.

In summary, our floors offer many benefits in industrial environments, including durability, chemical resistance, slip resistance, thermal resistance and hygiene. They help to improve safety, efficiency and productivity in industry and protect floors from wear and damage.

Industrial flooring in food processing plants is installed for several important reasons:

-

Hygiene: Our specially designed flooring systems help to ensure a high level of hygiene in food processing facilities. They are seamless, which minimizes the ingress of dirt, dust, bacteria and other contaminants. This reduces the risk of food contamination.

-

Easy to clean: Floor systems used in food processing facilities should be resistant to chemicals and easy to clean. They enable efficient cleaning and disinfection, which is crucial for food safety.

-

Resistance to moisture and chemicals: Spilled liquids and cleaning processes often result in residual moisture on the floor. A flooring system that is resistant to moisture ensures the longevity of the floor.

-

Slip resistance: Industrial flooring systems are designed to offer high slip resistance, even if they are damp or have food residues. This minimizes the risk of accidents and injuries in the workplace.

-

Legal requirements: Suitable industrial floors meet the strict requirements that the legislator places on food processing companies.

-

Durability: Industrial floors often have to withstand heavy loads and impacts in food processing plants. A high-quality industrial floor is hard-wearing and can withstand daily wear and tear without wearing out quickly.

-

Aesthetics: In addition to all the functional benefits, industrial floors can also be designed to be aesthetically pleasing. An attractive appearance can improve the working environment for employees.

An industrial floor can be extremely beneficial in larger retail outlets such as DIY stores and supermarkets. Here are some reasons why such a flooring system should be installed in stores:

- High load-bearing capacity: Larger retail stores often have intensive customer traffic and have to cope with heavy loads such as shopping carts, pallets and forklift trucks. An industrial floor is designed to withstand these high loads without damage.

- Hygiene: Maintaining high hygiene standards is essential, especially in food and beverage outlets. A flooring system that is free of joints and easy to clean reduces the risk of contamination and makes it easier to comply with hygiene regulations.

- Cost-effectiveness: Although an industrial floor may require a higher initial investment, it can prove to be a cost-effective solution in the long term. This is due to the reduced maintenance costs and longer service life.

- Slip resistance: In supermarkets, moisture – for example from wet footprints – increases the risk of slipping. A non-slip coating helps to prevent accidents and injuries.

-

Chemical resistance: Supermarkets often use cleaning agents and chemicals to maintain cleanliness and hygiene. A chemical-resistant coating system remains intact for considerably longer.

-

Food safety: In areas where fresh food is presented, compliance with food safety standards is crucial. A seamless, easy-to-clean industrial floor reduces the risk of contamination.

An industrial floor is extremely important and useful in commercial kitchens for several reasons:

- Hygiene: Maintaining high hygiene standards is crucial in commercial kitchens to ensure food safety. A seamless floor prevents the ingress of dirt, food residues and bacteria.

- Chemical resistance: In commercial kitchens, cleaning agents and disinfectants are often used to clean surfaces. An industrial floor is resistant to such chemicals.

- Slip resistance: In commercial kitchens, there is an increased risk of slipping due to liquids or grease. Our flooring systems are equipped with non-slip properties, which improves the safety of employees in the kitchen.

- Resistance to moisture: In commercial kitchens, moisture is created by cooking, cleaning and other processes. An industrial floor is resistant to moisture, which increases its durability and longevity.

- Durability: Commercial kitchens are heavy-duty environments with lots of movement, heavy equipment and continuous wear and tear on the floor. Our systems are robust and resistant to heavy use, allowing them to withstand daily demands.

- Fast installation: Time often plays an important role in commercial kitchens. Short installation times ensure minimal downtime so that normal operations can be restored quickly.

- Noise reduction: Some flooring systems can also provide a degree of noise reduction, which is beneficial in commercial kitchens to reduce noise levels and create a more pleasant working environment.

Overall, industrial flooring in commercial kitchens offers a wide range of benefits, including improved hygiene, safety, durability and resistance to the demands of a busy and challenging environment. It helps to increase operational efficiency and comply with legal regulations and hygiene standards.

An industrial floor is used in specialist vehicle businesses such as car workshops, in the vehicle industry and large maintenance halls for various reasons:

-

Durability: Vehicle operations often involve heavy equipment and vehicles that put a lot of strain on the floor. An industrial floor is robust and resistant to mechanical stress and wear, making it able to withstand daily demands.

-

Chemical resistance: Workshops often use oils, lubricants and other chemicals. Our durable coatings prevent damage or discoloration from contact with many substances.

-

Spilled operating fluids can pose a danger to employees. Our Qubo® floor systems can therefore be specially adapted to the required slip resistance.

-

ESD protection: In areas where electrostatic discharges can be harmful, such as in electronic assembly systems, an antistatic industrial floor can be used to protect electronic components.

-

Thermal resistance: Floors in vehicle operations can be exposed to increased temperature loads. An industrial floor has increased thermal resistance and retains its structure and durability even under such conditions.

-

Fast installation: Time is often an important factor in vehicle operations. Qubo® industrial floors are installed quickly to minimize downtime and allow normal operations to resume quickly.

Using an industrial floor in laboratories and development facilities, such as in the pharmaceutical industry, chemical laboratories, electronics laboratories or research institutes, offers various advantages:

- Chemical resistance: Laboratories and development facilities often use a variety of chemicals for research and development work. An industrial floor is chemical resistant and protects the floor from damage caused by contact with many chemical substances.

- Hygiene and cleanliness: In laboratories, especially in the pharmaceutical and food industries, a high level of hygiene is of crucial importance. Our coating systems are seamless, which minimizes the penetration of dirt and bacteria and makes cleaning and disinfection easier.

- Slip resistance: Industrial floors can be made slip-resistant to reduce the risk of accidents caused by liquids or damp surfaces and thus ensure the safety of employees.

- ESD protection: In electronics laboratories where sensitive electronic components are manufactured or tested, an antistatic top floor prevents electrostatic discharge and thus protects the sensitive components.

- Thermal resistance: Some laboratories are subject to elevated temperatures, e.g. during certain research processes or when working with high-temperature equipment. An industrial floor offers increased thermal resistance and therefore retains its integrity even under such conditions.

- Resistance to abrasion: In laboratories, heavy equipment, trolleys and laboratory furniture put a strain on the floor. A Qubo® coating is abrasion-resistant and withstands mechanical stress.

- Chemical and mechanical cleanability: Industrial floors are easy to clean and are resistant to the cleaning agents used in laboratories for cleaning and disinfection.

- Durability: Our Qubo® coatings are durable and can withstand the daily demands and stresses of laboratories and development facilities, extending the life of the floor and reducing maintenance costs.

In summary, industrial flooring in laboratories and development facilities offers numerous benefits. It helps to create a safe, clean and productive working environment and protect the floor from the specific challenges in these demanding environments.

An industrial floor is ideal for storage areas and offers a number of advantages:

-

High compressive strength: Our industrial floors are known for their exceptional compressive strength, which makes them an excellent choice for storage areas. Depending on the flooring system used, they can withstand point loads of up to 1000 kg per cm², which is essential for the use of heavy racking systems and forklifts in high-bay warehouses.

-

Durability: Storage areas are highly frequented areas where heavy loads are regularly moved. An industrial floor is extremely hard-wearing and resistant to mechanical stress, wear and abrasion, which significantly extends its service life.

-

Smooth surface: An industrial floor provides a smooth and even surface that facilitates the smooth movement of forklifts, pallet trucks and other industrial trucks. This helps to increase the efficiency of warehouse operations and prevent accidents caused by unevenness or tripping hazards.

-

Easy cleaning: Storage areas need to be cleaned regularly to maintain a clean and safe environment. Our floor systems are particularly easy to clean.

-

Antistatic properties: In warehouses where sensitive electronic components or devices are stored, an industrial floor with antistatic properties can be used to prevent electrostatic discharge and protect the sensitive goods.

-

Fire protection: Our coating systems have flame-retardant properties, which is an advantage in warehouses with flammable materials or goods in order to reduce the risk of fire.

-

Fast installation: Time is often of the essence in warehouses and high-bay warehouses. Our industrial floors offer fast installation and curing, which minimizes downtime and quickly restores warehouse operations.

In summary, our Qubo® warehouse flooring systems offer a range of positive features to meet the demands of warehouse operations. It helps to improve efficiency, safety and productivity in warehouses and high-bay warehouses, protecting the floor from the demanding challenges it faces on a daily basis.

An industrial floor is also ideal for wet and sanitary areas. In public toilets and showers – for example in gyms and industrial changing rooms – there are a number of reasons for using such a flooring system:

-

Waterproofing: Some industrial floors are specially formulated to be waterproof, making them ideal for wet and sanitary areas. They prevent water from penetrating the subfloor and provide an effective seal against moisture.

-

Hygiene: Hygiene is of crucial importance in wet and sanitary areas. Our industrial floors are seamless, which prevents the penetration of dirt and bacteria, making cleaning and disinfection easier. This helps to maintain hygiene in these areas.

-

Slip resistance: Our industrial floors can be made slip-resistant to minimize the risk of accidents caused by wet surfaces and ensure the safety of users, especially in showers and wet areas.

-

Chemical resistance: Cleaning agents and disinfectants are used in public toilets and changing rooms. An industrial floor is generally resistant to chemicals and prevents damage caused by contact with such substances.

-

Quick installation: In public areas, such as toilets or changing rooms, it is often important that the floor is installed quickly to minimize downtime.

-

Durability: An industrial floor is generally durable and resistant to wear and tear, which extends the life of the floor and minimizes maintenance and repair costs.

When choosing the right industrial flooring, the specific requirements of the area and the type of use should be taken into account. It is advisable to consult a specialist to ensure that the chosen industrial floor meets the specific requirements and hygiene regulations for wet and sanitary areas.

Industrial floors can be useful in public buildings such as hospitals, rehabilitation clinics, administrative offices and care homes for a variety of reasons:

-

Durability: Public buildings often have a high level of visitor traffic and are heavily frequented. An industrial floor is extremely hard-wearing and resistant to mechanical stress, wear and abrasion, making it able to withstand daily demands without any problems.

-

Chemical resistance: In certain public facilities, such as hospitals and care homes, cleaning agents and disinfectants are used to ensure high standards of hygiene. An industrial floor is resistant to many different chemicals and is therefore protected against damage caused by contact with such substances.

-

Slip resistance: In areas with high visitor frequency, such as corridors and stairwells, a non-slip surface is important to minimize the risk of accidents caused by falls. Our industrial floors can be designed to be slip-resistant for this purpose.

-

Hygiene: Hygiene is crucial in hospitals, rehabilitation clinics and care homes to prevent the spread of disease. Our flooring systems are seamless, which minimizes the penetration of dirt and bacteria and makes cleaning and disinfection easier.

-

Noise reduction: In public buildings, it is important to create a pleasant and quiet environment for visitors, guests and patients. Industrial flooring can provide a degree of sound insulation to reduce noise levels in open spaces and corridors.

-

Aesthetics: Although functionality and durability are the main arguments for a flooring system in public buildings, aesthetics also play an important role. Different colors and surface designs make it possible to support the interior design and create a visitor-friendly environment.

-

Easy cleaning and maintenance: Industrial floors are easy to clean and maintain, which is an advantage in public buildings with high visitor traffic.

Industrial flooring can also be used in guest and customer areas such as gyms, sports halls, exhibition halls, stadiums and changing rooms. The benefits depend on the specific requirements and activities in these areas:

-

Durability: In gyms, sports halls and stadiums, there is a high volume of pedestrian traffic as well as the movement of sports equipment and furniture. An industrial floor is extremely hard-wearing and resistant to mechanical stress, making it able to withstand constant demands.

-

Slip resistance: A non-slip surface is important in gym changing rooms to minimize the risk of accidents caused by wet floors. Industrial floors can be made slip-resistant to ensure the safety of guests and customers.

-

Chemical resistance: Cleaning agents and disinfectants are often used in fitness studios and sports halls. An industrial floor is generally resistant to chemicals and protects against damage caused by contact with such substances.

-

Noise reduction: In gyms, sports halls and other sports facilities, it is important to reduce the noise level in order to create a pleasant atmosphere. Industrial flooring also makes a contribution here.

-

Easy to clean: Industrial floors are easy to clean and maintain, which is important in public guest and customer areas with high footfall.

-

Aesthetics: Industrial floors can be created in different colors and finishes to enhance the aesthetic appearance of the premises and create an appealing environment.

-

Quick installation: In exhibition halls or temporary event locations, quick installation and removal of the floor is often required. Our industrial floors can be installed quickly and removed just as quickly if required.

Choosing the right industrial flooring

Choosing the right flooring system is a fundamental decision for companies. Retrofitting old floors in production areas reduces profitability during the conversion period. It is therefore important to make the right decision when choosing a high-quality industrial floor. The following factors should be taken into account:

Consideration of the company's requirements

First of all, the company should define its specific requirements for the floor covering. What kind of activities will be carried out on the floor? Will the coating be exposed to high loads? Does it need to be resistant to chemicals? Does it need to be antistatic? Is a non-slip surface required? These questions should be answered in order to make an informed decision.

Cost factors

Cost is also an important factor in the selection process. Costs vary depending on the type of flooring, the size of the area and the complexity of the installation. It is important to consider the long-term costs, including maintenance, repair and expected lifespan.

Installation process

The installation process can vary depending on the type of flooring. Some floor coverings require a complex installation, while others can be installed quickly and easily. It is important to plan the installation process in advance and ensure that it meets the needs of the business.

Choosing the right industrial flooring requires careful planning and consideration of various factors. A floor covering that meets the company’s requirements can help ensure that the company can work safely and effectively.

Maintenance of industrial floors

In addition to selecting the right coating system, regular maintenance is also crucial for a long service life and high performance. This chapter presents the most important aspects of maintenance.

Regular cleaning

First of all, the company should define its specific requirements for the floor covering. What kind of activities will be carried out on the floor? Will the coating be exposed to high loads? Does it need to be resistant to chemicals? Does it need to be antistatic? Is a non-slip surface required? These questions should be answered in order to make an informed decision.

Repair of damage

Even the most robust industrial floor can become damaged over time. Scratches, cracks or holes can affect not only the appearance, but also the functionality and safety of the floor. It is important to repair damage as quickly as possible to prevent further damage.

Conclusion: The advantages of industrial floors for companies

Industrial flooring is an important investment for companies that need a durable and long-lasting flooring solution. The right choice of coating system helps to improve productivity and safety in the workplace.

The robust and durable properties of industrial floors save companies money in the long term, as they need to be repaired or replaced less frequently. They also improve operational processes thanks to their ease of cleaning and adaptability to specific company requirements.

When choosing the right industrial flooring, companies should consider their specific requirements to find the best solution for their needs. It is important that cost factors and the installation process are carefully considered to make the best possible investment.

Through regular cleaning and needs-based maintenance, companies ensure that their industrial coatings maintain their optimum performance and longevity. In this way, they ensure long-term …

… for a strong appearance!

Non-binding cost estimate and advice

Link collection

- Worth knowing: Stone Carpet Systems – Mortar Floor

- Worth knowing: Epoxy resin floors in the industry