What is Qubo® Painting and who is offered airbrush motifs on stone carpet ? We provide answers to all your questions about stone carpet logos.

What is Qubo® Painting?

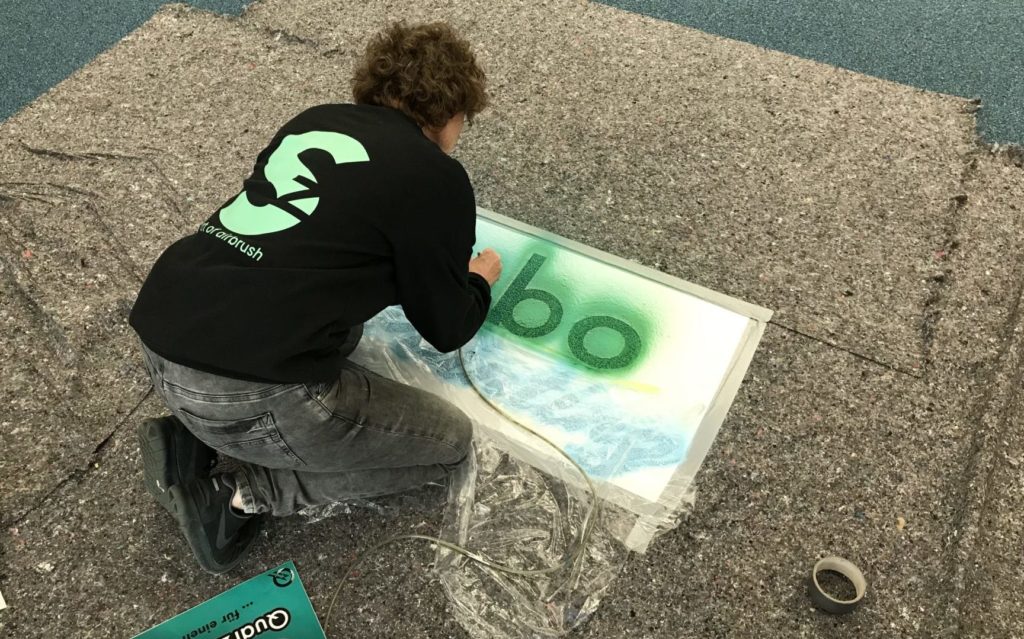

An invention of sz art of airbrush

To understand why it is always worthwhile to offer a Qubo® Painting stone carpet logo, it is helpful to know

- what Qubo® painting is,

- where it comes from and

- how it works.

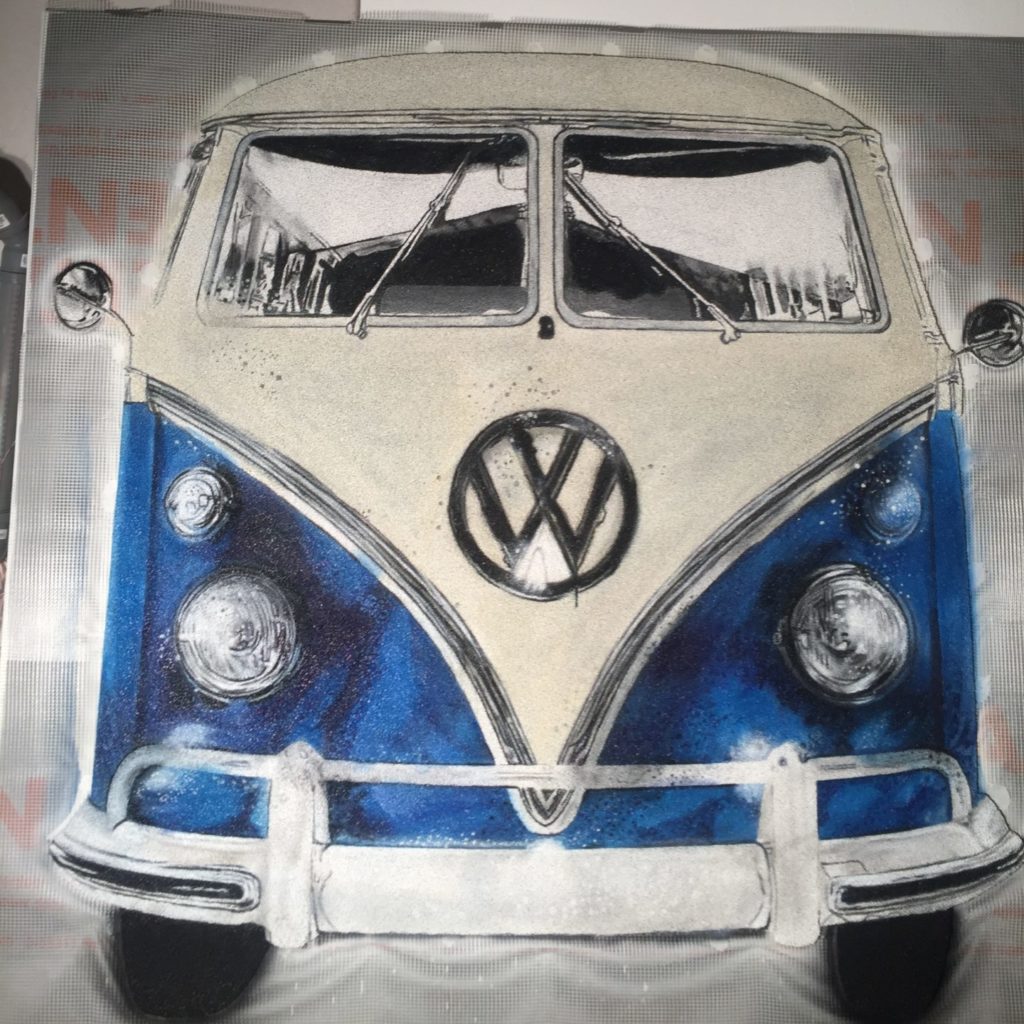

Qubo® Painting describes the creation of logos and motifs using the airbrush technique on Qubo® stone carpet . The term itself originated from the cooperation between sz art of airbrush , the initiator of Qubo® Painting, and Quarzkiesboden Zimmermann GmbH & Co KG, the supplier of Qubo® flooring systems. The Qubo® Painting system stands for professionally laid gravel floors with high-quality airbrush designs under a durable sealant.

For the customer, this means almost limitless possibilities for individualization in the commercial sector, home and garage. For certified installers, Qubo® Painting is the ideal way to set themselves apart from the competition and expand their portfolio and customer base with unique products.

The participants of our recent Qubo® Painting training course did not want to miss out on this opportunity.

Why is Qubo® Painting better than other techniques?

Vorteile von Qubo® Painting erfahren

Of course, Qubo® Painting is not the only technique for creating stone carpet logos, texts or images on floor surfaces. For example, inlays can be worked into wooden floors, small-scale mosaics can be created on tiled floors or stone-in-stone patterns can be laid into conventional gravel floors. However, these lead to longer construction times, as the necessary work steps are either very time-consuming or lead to unavoidable breaks.

On the other hand, the design options in these cases are much more limited than with Qubo® Painting.

Wood inlays are usually kept in natural colors, mosaics either come in the form of prefabricated tile panels without individualization or are extremely complex to produce. Stone-in-stone logos delay construction by another day for each desired color.

Qubo® Painting combines all the advantages in one system: the airbrush technique enables the creation of detailed light and shadow effects and reflections that would hardly be possible with other products. The artwork can be prefabricated before construction begins and only needs to be finished when the floor is laid.

What’s more, the stone carpet logo lasts just as long as the gravel floor: As the decorated areas are sealed in the same way as the flooring system itself, frequent foot traffic, thorough cleaning and weathering are no problem. This means that abrasion-resistant logos can also be used outdoors.

Logo creation in the studio or directly on the construction site How are stone carpet logos created?

The basis for the motifs created with Qubo® Painting is a professionally laid Qubo® stone carpet . Depending on the planned motif, the artwork can be created freehand or with masking film in advance of the construction site or at the installation site itself.

The gravel grain size determines the possible level of detail in the images: The finer the grain size of the quartz gravel used, the finer the details that can be displayed.

How are stone carpet logos made durable?

Seal stone carpet logos accordingly

Once the design has been incorporated into the floor, the floor can either remain open-pored or be sealed, depending on the area of application and customer requirements. Many flooring systems change their appearance when sealed. Wood, for example, loses its natural effect under an epoxy resin seal. Tiles must be roughened or scattered before sealing. Stone carpeting, on the other hand, consists of quartz gravel and epoxy resin, so that the individual pebbles are already sealed after laying. Accordingly, the look does not change even after a sealing layer. As all seals offered by Quarzkiesboden Zimmermann are transparent, the original impression of the logo is completely retained.

Together with the selected grain size, this results in a wide range of possible applications:

- Welcome greeting in the entrance area with protection from dirty shoes

- Company logo on the store floor that can withstand heavy footfall

- Marking of industrial floors in production halls with company logo & lettering as well as dirt-repellent sealing

Three good reasons why a stone carpet logo is a brilliant idea Are you committed to your corporate design? Show it!

The three application suggestions already show the diverse areas of application of Qubo® Painting. Accordingly, your corporate identity does not have to end with uniforms or e-mail signatures. Make your store or production area part of your branding with a stone carpet logo. In this way, your logo and slogan will become an integral part of the company and will be as memorable as the motif on the stone carpet .

Anyone can do standard - Stand out from the crowd!

We ignore so many things in everyday life because they hardly stand out from the modern uniform look. This makes the psychological effect of an unexpected feature such as the greeting at the entrance with artistically designed lettering all the more powerful! As we all know, there is no second chance to make a first impression. So turn a visit to your building into an experience with a stone carpet logo.

Diversity and creativity pay off!

The same applies to publishers: being better than the competition is an important selling point for your own products. Those who can shine with special service and unique products increase their chances on the market. In this way, a stone carpet logo quickly creates effective advertising references, which in turn inspire new potential customers.

Who can create a Qubo® Painting for me?

Interested in a stone carpet logo?

If you have already come up with the first ideas for your desired motif while reading this, your contacts at Quarzkiesboden Zimmermann and sz art of airbrush will be happy to help and advise you. Together with you, we will…

…for a strong appearance!

Link collection

- Product pages

- sz art of airbrush (Erfinderin des Qubo® Painting Steinteppich Logos)

- Worth knowing: Cleaning and maintaining stone carpets

- Contact to Quarzkiesboden Zimmermann

As the stone carpet logos from sz art of airbrush are produced in advance and delivered to the construction site ready for laying, the gravel floor and airbrush logo can be laid in one go. This means that construction is not delayed.

Yes, the UV-resistant sealant ensures that the colors of the stone carpet logo are absolutely lightfast.

Yes, because the stone carpet logos are coated with a sealing layer after creation. This sealing layer, together with the airbrush colors specially matched to the gravel floor and the sealant, makes the motifs just as abrasion-resistant as the flooring system itself.

Stone carpet logos are used wherever the use of motifs makes sense or is simply desired. In the private sector, for example, favorite animals or family coats of arms are often incorporated into the floor. In the commercial sector, company logos are mainly used, but also company-related motifs and lettering.

On the one hand, you can contact the sz art of airbrush manufactory directly. If you wish, we can recommend suitable stone carpet laying companies.

The second option is to contact Quarzkiesboden Zimmermann. We can provide you with information on all aspects of stone carpet logos and installation.

You can also order the stone carpet logos directly from your installer.

First and foremost, the area of application of the stone carpet determines the pricing. However, the costs depend on many different factors, including

- the type of binder required

-

from the primer

-

the choice of skirting boards, for example if these are also made of quartz gravel

-

from the labor costs of the professional installer

-

the size of the area to be laid

In outdoor areas, the costs are higher because the substrate needs to be sealed and the marble gravel needs to be laid with a UV-resistant binder.

In most cases, colored quartz or marble gravel is used for the production of stone carpets. However, there are considerable differences in quality here, for example in the proportion of dust in the material or the types of marble used.

Mica additives and various precious and semi-precious stones can be added, but this is another cost factor.

Colored quartz is available in the following grain sizes:

-

1–2 mm

-

2–3 mm

- 3–4 mm

Marble gravel is available in the following grain sizes:

-

1–4 mm

-

4–8 mm

- 8–15 mm

Of course, the choice of gravel grain size has an effect on the laying thickness of the gravel floor.

The laying thickness of the floor depends on the gravel grain size and the area of application. Normal quartz gravel with a grain size of 2 – 3 mm can be laid indoors with a thickness of 6 mm.

An installation thickness of 8 mm is used outdoors and on stairs indoors due to the load.

Finally, 10 mm of material is applied to external stairs.

Vertical surfaces such as risers, skirting boards and walls are always laid in 6 mm.

The larger the grain size of the gravel, the higher the installation height of the floor covering. This means that more gravel and additional binder is required per m². The price increases accordingly.

The primer forms the bonding bridge between the building structure and the gravel floor. The material can be applied to almost any substrate, for example tiles, wood, stone, concrete and metal. Different substrates require different preparation steps.

On tiles and metal, for example, a primer is required to give the smooth surface stability during installation.

On porous stone and absorbent screed, the appropriate primer must be used to prevent the binder from being absorbed, which is intended to ensure that the pebbles remain in place.

To coat wooden planks with a gravel floor, the movement of the planks against each other must first be stopped. To do this, the installer first applies a mesh mat to the wooden floor. Once the filler has dried, the gravel floor is applied.

In kitchens and bathrooms in particular, the stone carpet should be fitted with a pore seal for reasons of hygiene. It prevents leaked, sticky liquids from penetrating the gravel structure. While penetrating liquids are difficult to remove from an open floor, the pore closure allows effortless cleaning by wet mopping.

Dogs, cats and the like feel much more comfortable on the structured surface than on smooth floor coverings such as tiles or laminate, as they do not slip on the gravel structure. However, it is advisable to apply a pore sealant to the floor to ensure an easily wipeable surface.

-

High drainage capacity due to open-pored structure

-

Quick drying in sun and wind

-

Easy to clean and self-cleaning

-

100% frostsicher

-

UV-stabil

- Gentle, massage-like walking comfort when walking barefoot

- Use of absolutely lightfast stone carpet logos possible

The most important thing when laying gravel floors in outdoor areas is preparing the substrate. This ensures the durability of the finished floor.

On the one hand, this is because a primed subfloor provides significantly increased adhesion for the filled gravel. On the other hand, a sealing layer keeps rainwater away from the building structure, for example, which supports long-term durability.

Options for sealing building structures are

- Sealing using an epoxy resin seal with sealing membrane

- Sealing using a flex sealing slurry

In order to drain rainwater effectively, the floor covering is laid with a gradient of at least 1.5%.

Just like indoors, the stone carpet logos are also used and applied directly to outdoor surfaces during installation.

No, in outdoor areas, the stone carpet is always laid as an open system to ensure drainage capacity and thus the drainage of rainwater. This makes them 100% frost-proof and therefore ideal for pool surrounds and as a covering for balconies, terraces, entrance areas, outdoor staircases and loggias.

We would like to point out that we do not recommend stone carpets in the direct shower area. The reasons for this can be found in the basic structure of the floor and the wet room. Just as the tile adhesive under a tile does not form a completely flat surface without air pockets, pores also remain underneath a sealed gravel floor.

If, after years, a silicone seam leaks and water from a fitting, for example, penetrates between the wall or floor covering and the seal of the building structure, the transparent pore seal reacts with the water and forms white stains. As these occur underneath the seal, they cannot be wiped away or removed by drying.

This is why insurance companies do not classify stone carpets as suitable for wet rooms and do not replace such coatings in the event of damage. We therefore recommend microcement coatings for showers. With these, there is no water-bearing layer between the floor covering and the substrate, so there is no risk of moisture penetration. Due to the many customization options for microcement, it can also be combined with a gravel floor. Just get in touch with us.

Yes. A staircase coated with stone carpet already has a slip resistance class of R10 after installation.

Special sealants can be used to increase the slip resistance class to R11 or R12.

Depending on the design of the staircase, the renovation takes 3-5 days. In special cases, installation is also possible within an even shorter time. For a more precise determination of the duration of your construction project , simply contact us at.

All our gravel floors use natural stones as the base material. This is why many people also refer to stone carpeting as natural stone carpeting.

The gravel is available natural and colored.

FAQ

Details and facts, key figures and explanations – here you will find answers to frequently asked questions about our Qubo® coating systems. If any details remain unclear, simply contact us. We will be happy to advise you personally and promptly.